WHY STEEL SERVICE CENTERS ARE PIVOTING TO HIGH POWER, LARGE FORMAT LASERS

February 5th, 2026

For decades, Steel Service Centers have used HD plasma cutting systems paired with Hypertherm HPR400XD plasma with drilling, tapping and marking capability. Proven, versatile and cost effective, this technology delivers reliable everyday fabrication while excelling in heavy plate, beveling and applications where robustness and low operating costs are critical.

Fast forward to today, laser technology has evolved rapidly, with large format, high power laser cutting machines reshaping how many service centers view plate cutting.

Breaking the 1:1 Ratio: High-Precision Hole Cutting

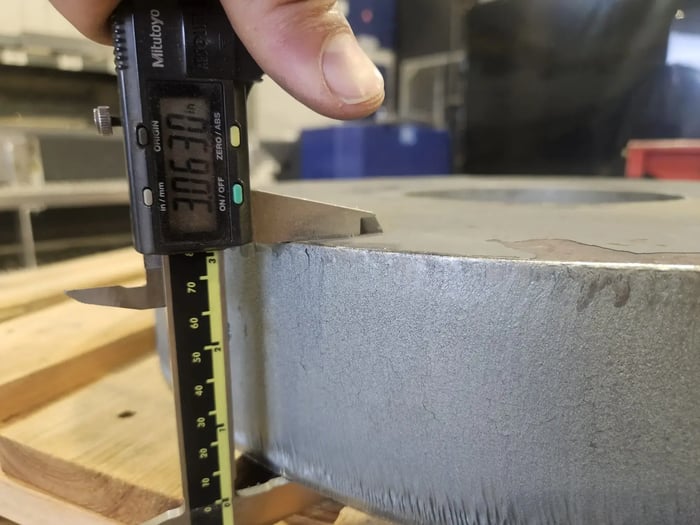

One of the important aspects of high power laser is the ability to to cut holes smaller than the material thickness (as small as 1:4 or 25%) with production quality, something that still is not possible with plasma technology. It is a game changer for service centers, since what could necessitate multiple processes or drilling, can now be done in one pass.

Autonomous Setup: Beam Centering and Nozzle Management

Two important options to look for are automatic beam centering and nozzle changing, which allows for switching seamlessly between materials and thicknesses without operator intervention. The beam centering assures consistent cut quality and longer consumable life by keeping the beam centered in the nozzle, while the nozzle changer can select, remove and install the correct nozzle.

Material Versatility: Cutting Non-Laser Grade and Oxidized Plate

Today’s high power lasers (30kw+) are no longer limited to pricy laser grade material. They can reliably cut standard mild steel, including scaled or rusty plates, removing the historical requirement for costly material. This provides economies of scale and make lasers more accessible to steel service centers than ever before.

Operational Safety: Enclosed Cutting and Pallet Exchange

From a shop floor perspective, laser systems also provide other advantages, such as the enclosed cutting zone, resulting in a cleaner environment with minimal dust, fumes, light radiation and noise versus open air high definition plasma cutting. The pallet changer or the separate zones on larger format lasers improves operator safety by isolating the active cutting zone, leaving previously cut plates to be unloaded safely.

Advanced Piercing and Gas Mixing for up to 4” Mild Steel

Finally, one of the most important advantages is the wide range of materials and thicknesses high power lasers excel at. New lasers can consistently cut faster in almost all thicknesses, while providing intricate cuts and designs and allowing up to 4” mild steel cutting. Aluminum and Stainless Steel continues to be right in the wheelhouse of lasers, with great quality and finish. What enables this versatility is the newer gas technologies, from gas mixing for ultimate performance and finish to N2 or O2 speed cut technologies.

Are HD Plasma Cutting Systems Obsolete?

None of this makes HD plasma obsolete. On the contrary, HD plasma with drilling, tapping and machining remains an essential technology for thick plate, structural components, and demanding industrial environments. However, for many service centers, large format laser cutting represents the next logical step, either as a complement to existing plasma systems or as an expansion into higher-precision, higher-throughput applications.